Revolutionizing Aerospace Engineering

Revolutionizing Aerospace Engineering

Revolutionizing Aerospace: Breakthrough 3D-Printed Alloy with Superior Crack Resistance

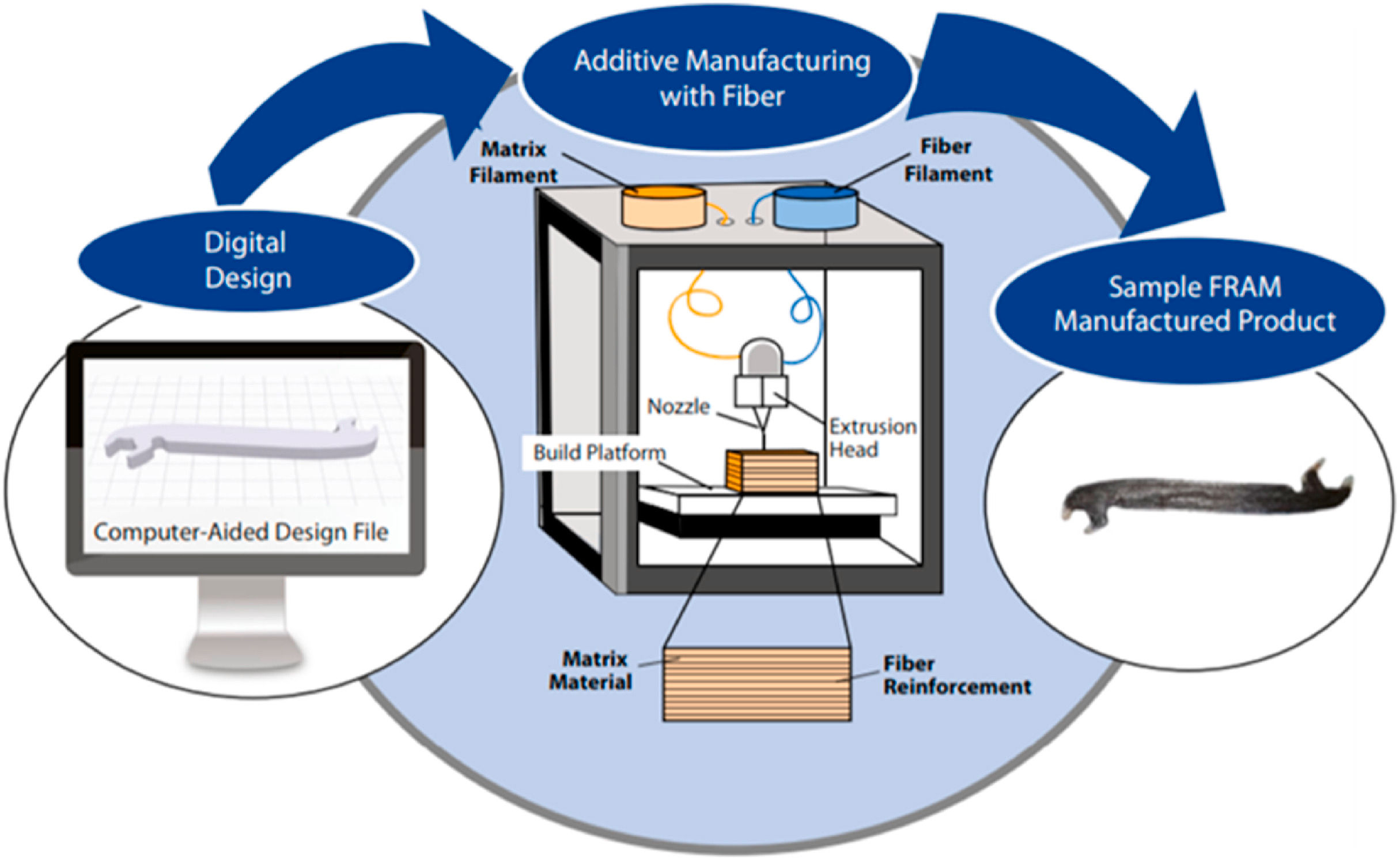

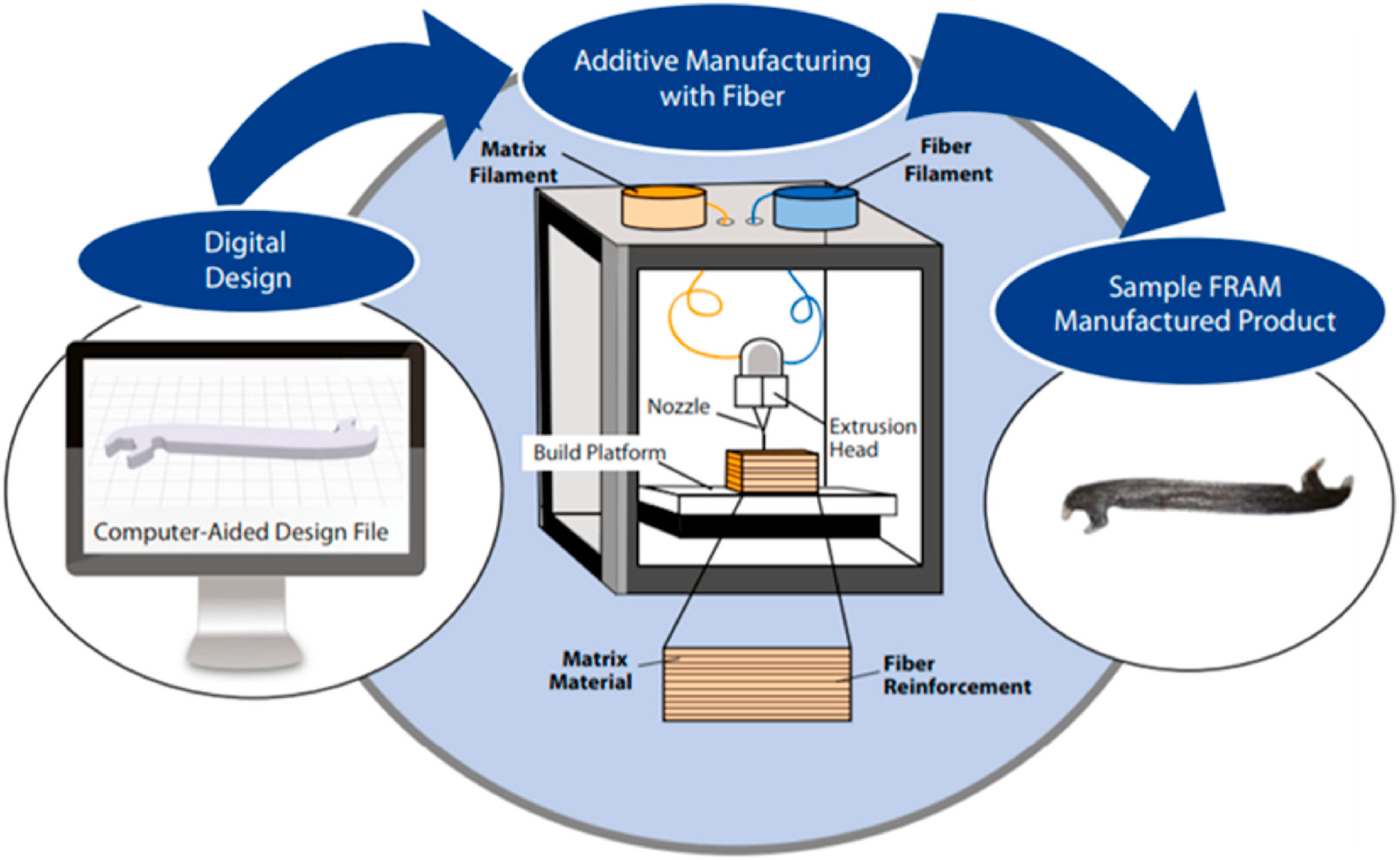

Additive manufacturing (AM) is transforming modern fabrication by constructing objects layer by layer directly from CAD models. Known for its innovative, cost-effective, and eco-friendly approach, AM has become the fastest-growing technique in industry. Initially used mainly for prototyping in aerospace and automotive fields, recent advancements now demonstrate its efficiency in producing fully functional components. Research also highlights AM’s alignment with the Sustainable Development Goals (SDGs), showcasing its role in promoting sustainability and efficient resource usage. A key breakthrough in the field is the development of 3D-printed, crack-free alloys for turbine blades, designed to be lightweight, durable, and capable of withstanding extreme temperatures. This advancement in materials science enables high-stress applications in the aerospace and automotive industries, offering a resilient, heat-resistant alloy that reduces weight while maintaining structural integrity. These advanced metals not only enhance performance but also reduce manufacturing costs, waste, and resources, paving the way for innovative and complex design possibilities in additive manufacturing.

The process of developing components through additive manufacturing begins with computer-aided design (CAD), where engineers meticulously craft detailed models tailored to specific applications. Once the design is complete, it is converted into a standardized format that accurately represents the 3D geometry of the component. This formatted model is then transferred to an additive manufacturing machine, where the component is built layer by layer, precisely following the digital model’s specifications. After fabrication, various testing and characterization methods are applied to assess quality, optimizing process parameters to ensure the final product meets rigorous standards. Through this cycle of testing and refinement, the component is produced under optimal conditions, resulting in enhanced performance and reliability.

The introduction of this alloy could transform the aerospace industry, enhancing the safety and efficiency of aircraft. As manufacturers adopt this technology, the potential for lower production costs and improved sustainability becomes more attainable. Industry experts believe this breakthrough will play a key role in developing the next generation of aerospace vehicles, opening doors to future innovations in the field. In conclusion, the development of crack-free alloys through 3D printing marks a promising leap forward in materials science, with the potential to improve performance, reduce waste, and enable innovative designs across industries. Ongoing advancements in this area are likely to lead to broader applications and greater efficiencies in the years to come.

Image credits to original Authors DOI: 10.1016/j.heliyon.2024.e27328

Reference

Noshin Tasnim Tuli, Sinthea Khatun, Adib Bin Rashid, ‘Unlocking the future of precision manufacturing: A comprehensive exploration of 3D printing with fiber-reinforced composites in aerospace, automotive, medical, and consumer industries’. Heliyon, Volume 10, Issue 5, 2024, e27328, ISSN 2405-8440, DOI: 10.1016/j.heliyon.2024.e27328